CubiScan : Optimise your supply chain !

The size and weight of products in a supply chain are very important.

Distribution operations have access today to powerful software for managing demand, orders, warehousing and transportation.

For these to operate effectively, they should have access to accurate product data such as bar-codes, sizes and weights. If this data base is inaccurate, the supply chain and product costs are not being controlled.

CubiScan resolves these issues - with rapidity and precision.

Validate your data base

• The merchandising department is typically responsible for specifying the technical and commercial details of new products and then transmits these to the purchasing department to determine demand and then initiate procurement.• The basic product data such as dimensions, contents and weights of product packaging are essential if store-specific planograms are to be exploited.

• Product margin simulations require accurate data on the costs of storage and transport throughout the supply chain. This, in turn, requires accurate cube and weight information of the various handling and storage methods - pallets, roll cages, totes, cartons etc...

The beginning - the reception bay

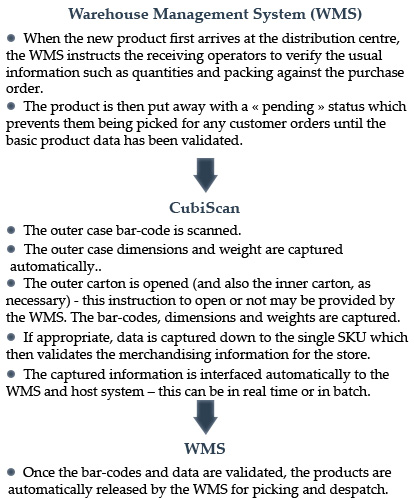

• The distribution centre is typically the first point of supply chain contact for a new product and the appropriate data capture must start at the reception bay.• Bench-marking by CubiScan customers indicate that the following work-flow represents best practice in the majority of operations :

Distribution center ROI

• Accurate data for improved picking and order preparation improves the fill of cartons, roll cages, pallets etc...• Precise cube and weight information optimises put away and pick slot management by the WMS.

• Greatly improved vehicle fill due to optimised product and packing cubing.

• Precise weight and dimensions improves control of transport costs - sub-contractor over-charging easily identified.

Shop ROI

• Pre-validation of code-bars reduces errors at point-of-sale.• Product dimensions are validated for use by the store layout software.

Company ROI

• Supply chain transport delivery costs reduced due to improved vehicle fill.• Improved customer service due to pre-validated bar-codes avoiding customers waiting at tills due to unknown bar-codes.

• Reduced storage and handling costs due to access to accurate data by supply chain management software.

Getting started

• The first step is to capture the caracteristics of all the products currently in stock.• This can be carried out by creating pick instructions for each product and taking them to a CubiScan in a fixed place. A more efficient method is to use a mobile CubiScan, which runs on a battery and inverter, and move it to each picking location. One operator can treat between 450 and 650 products per day..

• Once the stock data has been captured the CubiScan is then typically moved to the reception area to be used for each new product as it arrives.